LENZA ONE

2015, University of Brighton

Motorcyclists are frequently exposed to high levels of wind noise, which can lead to discomfort, reduced awareness and permanent hearing damage. I set out to develop a solution and this helmet design is the result of my work.

This project received considerable recognition from the motorcycling industry. It was featured in multiple print & web publications, demonstrated at New Designers, London (2015) - and won a prestigious award by the Institute for Engineering Designers (IED). I was also invited to BBC Sussex Radio, to talk about the project live on air.

Find out below how I developed this project.

As featured in

PROCESS

Challenge

Less than 20% of motorcyclists regularly use ear plugs and most are mistaken that their helmet provides adequate protection against noise. Hearing damage will also occur over an extended period of time, thus not always showing immediate effects after a ride. The combination of lack of user knowledge and a long-term cause, means this problem has not received the attention it deserves. Lenza One was developed to combat this issue.

“Lifelong, irreversible damage and constant suffering”.¹

Frequent exposure to these levels will lead to Tinnitus - a major cause of suicide”. ²

“70 mph will produce roughly 100dB”. ³

Research

A variety of research techniques were applied, including literature reviews, contextual inquiries, interviews with occupational riders and a survey of 80 mixed riders. A lot of data was collected over the course of 3 months, resulting in many key findings. The primary research highlighted the behaviors and attitudes of riders, whilst secondary research identified the primary causes of noise.

-

At riding speeds, the helmet operates in such a way that it actually amplifies low frequency sounds. This is caused by the resonation of the helmet under wind turbulence. The sound is translated through vibration⁴

Ideation

The exciting part - idea generation! This phase of any project is fundamental to discovering novel solutions. Proven techniques can be applied to help encourage new ideas to surface, whilst working in teams can dramatically improve the breadth of results. I employed a number of methods, including; brainstorming, storyboarding, Scamper, 6 hats and more. After refining the ideas to 50 or so, I used a NUF test and Pugh matrix to determine which concepts were best to pursue.

Early testing

After refining ideas to viable concepts, 'sketch modelling' is carried out to obtain a fast, 3-dimensional representation of each concept. This is a great way to visualise ideas and provide a tangible point for discussion point.

Further models were created for early functional testing, to help validate the effectiveness of various ideas. My early functional models included a plastic shell, air blower and a decibel meter app, to compare different suspended surface configurations. Although the results are not definitive, they help to guide early research and development.

Design

The design features a top-mounted suspended shell, which absorbs wind vibrations - the primary cause of harmful noise frequencies. The optional suspension mounts vary in stiffness, to compensate for different frequencies of vibration, to suit varying use cases (racing vs. courier). It also incorporates a series of dimples on the surface, to help to improve airflow and reduce turbulence (a secondary cause of noise). A third feature of the design is its elongated form, to further mimic the streamline teardrop shape.

Testing

At this point the design is only function in principle, so a series of tests were carried out to validate it's effectiveness at reducing noise. First off, I performed CFD (Computational Fluid Dynamic) tests in software. This is a practical and fast way to determine the influence of different design features. These tests were used to optimise the design. Some interesting results were gained when compared with a market-leading Arai helmet. A reduction of turbulent air in the wake region (rear of the helmet) of 7.7% was achieved, resulting in less vibration.

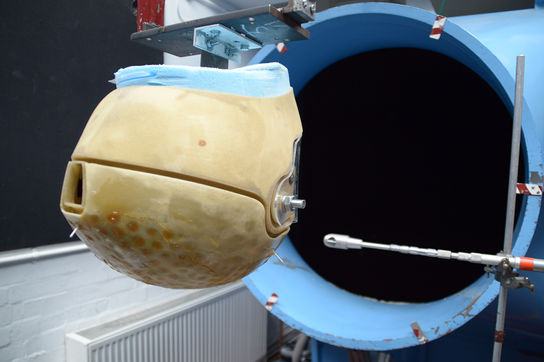

After 3D printing the final design, I ran some physical tests in the wind tunnel. I was able to compare the design with a conventional design, by restraining suspension and covering the dimples. The measurements were not easy to capture, so the integrity of the results can be questioned. The improvements were not dramatically better, but through more optimisation of the design and better test conditions, the margin for improvement could be larger.

Prototyping

The development of the 1:1 scale aesthetic model was the most rewarding stage - to finally realise the design. The main shell was 3D printed, and finished by hand. The Acrylic visor was heat-formed and ancillary components made by hand to. I take pride in the craftsmanship of producing prototypes and its great to see the final result.

Exhibition

I was fortunate enough to feature the design at two exhibitions, in the summer of 2015. One at the University of Brighton and secondly at a large event in London, called New Designers. It was great for the design to get exposure, and several publications wrote about my work. After it was featured, other reporters from around the globe published the same story - from France to Japan. I also won a prestigious award from the Institute of Engineering Designers (IED), a national body within the UK.

Accolades

2015 - Institute of Engineering Designers - Degree Project Award

2015 - BBC Sussex - Radio interview

2015 - Motorcycle Sport and Leisure magazine - Full-page article

2015 - More Bikes - Audio interview and Article

References

-

1,4: N Holt, 2013.

-

2,3: M Carley, 2013.

Share this project!